Forum Replies Created

-

AuthorPosts

-

in reply to: Randomly Changing Settings #4000

@rocketscream wrote:

Anyone else is facing this issues besides Sand and Cracked?

I haven’t experienced any weird parameter changing – thankfully.

Brett – thanks very much for your reply. You’re absolutely correct about the system behaving differently at ~40C relative to 100C (where my setpoint will be most of the time). I’ll keep this in mind.

If it matters so much if the initial output is 100% when I start my process, it seems that the best solution is to use a temperature profile to artificially add a breakpoint in the middle of the big temperature rise to get the espresso boiler from cold (~20C) to brew temp (~100C). If all goes well with this “breakpoint” in the middle, I will see the temp overshoot fairly dramatically at, say, 75C. This overshoot will cause the PID output back off significantly before I ramp the temp up to the final brew temp of ~100C. Because the output has dropped so much as a result of this breakpoint, I’ll effectively start from at or near zero output at ~75C, which is closer to my brew temp, and therefore more appropriate for the PID tunings.

I think I’m starting to get it… Please let me know if I’m off base on any of this.

I’ll follow up with success stories/results soon hopefully.

in reply to: Autotuning #3851Thanks for the reply, Brett. I just want to respond and close the loop on your comment concerning the nature of heating a tank of water. You do raise some interesting questions concerning the non-linearity of the process (hence exhibiting varying degrees of good or bad control based the temperature of the system when the autotune process was executed).

If I can read between the lines here a bit – it seems that the osPID can certainly accommodate a control strategy that does account for system non-linearities (losing heat to the walls of a tank), but you haven’t included this capability in the code because of intellectual property issues or simply a lack of memory. Is that a fair estimate?

Is it possible, using the standard equipment on board, to program the osPID such that it can control the temp of water in a tank going from cold (room temp) to boiling? I just want to know what the osPID is capable of doing so I can switch gears and start digging into code modifications rather than trying to find the magic PID parameters via trial and error testing.

in reply to: Thermocouple grounding #3978@hairykiwi – I’m afraid I can’t claim to be using a particularly smart solution. I’m simply using a standard bead K-type thermocouple (the absolute cheapest, simplest K-type thermocouple). In order to isolate the metal bead at the tip of the TC, I’m simply wrapping the tip with tape! To measure the temp of the boiler of my espresso machine, I’m simply using a zip tie and some neoprene insulation to hold the TC firmly to the boiler wall.

in reply to: Autotuning #3847Perhaps I’m missing something about the autotune process.

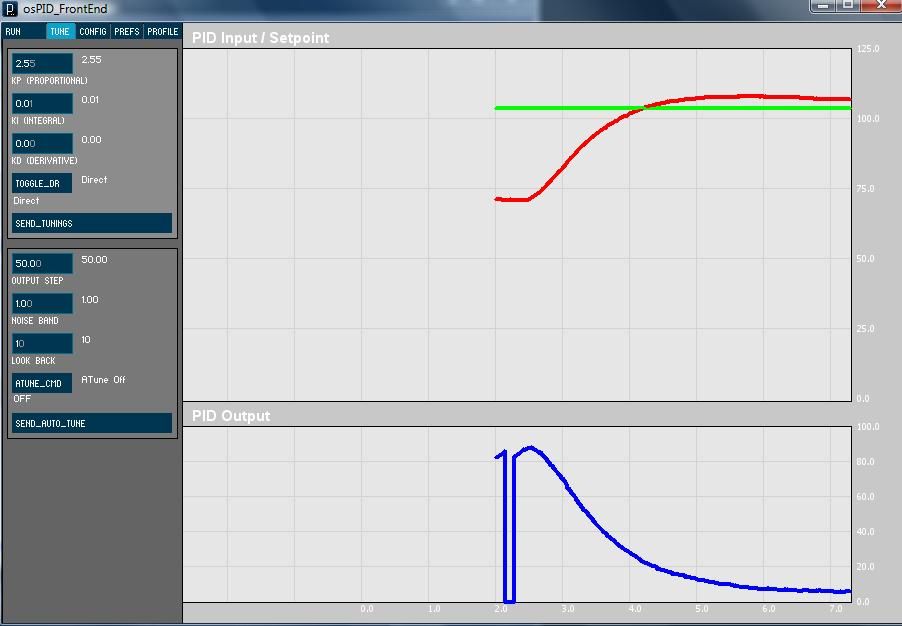

I’ve put my system (an espresso machine) near the setpoint temp and executed autotune as described in this thread. The result of that process yields: Kp=2.55, Ki=0.01, Kd=0.0. However, when I actually use these tuning parameters to run my system, bringing water up from ambient to setpoint brew temp, the following results are achieved (that initial blip in the output is just me taking the output from manual to automatic before starting the run):

So if the autotune parameters are used, then there is still a material degree of overshoot. Why is this?

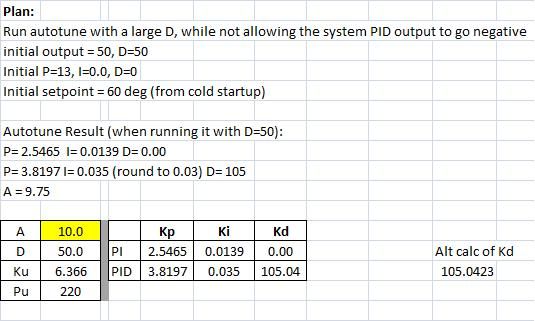

Not knowing the answer to this question, I thought that the system should include a Kd parameter to help anticipate the overshoot before it occurs. Rather than taking the manual guess ‘n check approach, I looked at the Autotune description page (http://brettbeauregard.com/blog/2012/01/arduino-pid-autotune-library/) to read up and try to calculate the Kd parameter that I think I need. Using the Autotune inputs that I used to get the above parameters, I calculated a set of PID parameters that *should* make sense, or at least be reasonable – they are Kp=3.82, Ki=0.04, Kd=105.04 (see below for a snapshot of my calcs)

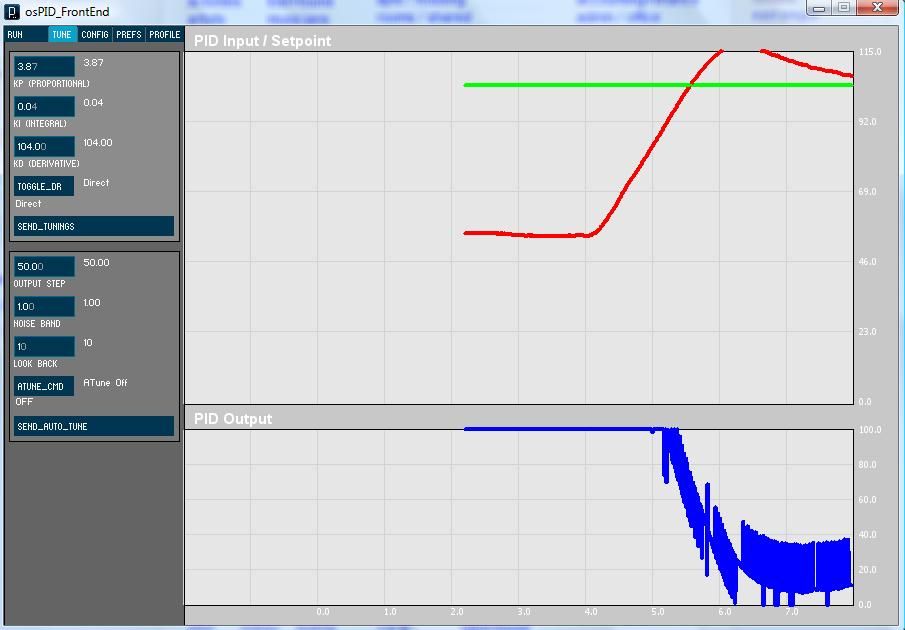

Ok, great! Let’s take this for a spin:

Whoa – that’s a lot of overshoot – and a lot of noise around that output line!

Now I’ve lost a lot of faith in the ability of Autotune to point me at all in the right direction. What’s going on here? Why would Autotune give me only PI parameters and not PID parameters? Are my tuning problems associated with the fact that the delta between cold startup temp and brew temp is so large (approx 80C)? Is there a way to force Autotune to perform a test over a much larger temperature span (producing oscillations from, say, 20C to 100C)?

I’ve done over 65 test runs to manually tune the PID (each at over 5 min test time) and I’m losing my patience with the manual approach as well. Any input to the above questions is appreciated.

in reply to: SSR Behaviour #3989Check to make sure that your PID output isn’t going below zero. If that happens, then the system gets confused and turns the heater on.

You might also check if you have insulation of some kind that is storing heat somewhere. Over a long enough period, your system should absolutely return to ambient temp (much shorter if you’re aspirating the system in some way).

in reply to: Ramp Soak and stuff #3747I’m having fun making profiles on my own now.

One suggestion: It would be great to have the ability to choose from one of several pre-loaded temperature profiles from the on-board interface. I may try to implement this myself. If I’m successful, I’ll share whatever it is that I come up with.

in reply to: Thermocouple grounding #3976Thanks for the input. I have switched over to an isolated thermocouple to measure temperature. I’m having success with this approach now.

-Dan

in reply to: Ramp Soak and stuff #3745@Brett wrote:

I’m currently working on making a SP profile generator for the front-end, but currently all you can do is hard-change the setpoint.

Hi Brett,

I’m in the process of rummaging around in the source code to create my own setpoint profile to 1) heat an espresso machine boiler tank from cold to full brew temp (~100*C) and 2) maintain that brew temp in steady state.

Before I dig any deeper, I’m wondering about this profile generator that you mention above. Is this planned as a release some time soon? Thanks for any update you can share with us.

In the mean-time I’ll continue to slog through the code in hopes of piecing together a clever profile.

It’s all good fun if you ask me!

Thx,

Danin reply to: Autotuning #3846.

in reply to: Wierd Input error and hard to get no overshoot. #3955Make sure your thermocouple is not grounded. I had a similar temperature reading once when my thermocouple was bouncing between being grounded and ungrounded.

in reply to: Arduino Reflow Oven Controller Shield #3925@redwire wrote:

Your power supply for the OpPid (especially if it’s a SMPS wall-wart) adds noise, so you need to have a ground wire from the OpPid to the metal chassis and earth-ground

Can we get some clarity on how to ground the osPID? I see a GND pin hole connection inside the box on the input card, but is this what should be used to ground the whole osPID?

Any input from others would be helpful.

Thanks,

Danin reply to: Thermocouple grounding #3974Thanks for the help, Kevin. I believe this noise issue has been resolved in a bug fix released by the developers (http://www.ospid.com/docs/index.php?title=Temperature_Input_Card_v1.2_BugFix)

All other readers: Note that I’ve edited my original post to clarify my question a bit. Please have a read above and let me know if anyone else has experience with grounding the osPID.

in reply to: Thermocouple grounding #3972Further to the above post, I’m also experiencing considerable noise in my thermocouple measurement (I am using this TC: http://www.omega.com/pptst/WT.html). Any input regarding filtering techniques would also be appreciated.

Thanks,

DanHi Sith6,

Can you provide any details about the thermocouple that you ended up using? Is there any need to amplify the voltage signal in order to get accurate readings at the PID? Any detail that you can provide on this would be helpful to me. Also, I’m curious how you attached the thermocouple to the water boiler.

Thanks in advance,

Dan -

AuthorPosts